With thousands of acres of seagrasses dying in estuaries across the state, resource managers are desperately searching for innovative ways to restore the critically important habitat. Ground zero in that effort may be a renovated fish farm located just east of Tampa, where a team led by Beau Williams at AquaTech Eco Consultants is developing the largest seagrass aquaculture system in the state.

He’s working hand-in-hand with Tom Ries, president and founder of the not-for-profit Ecosphere Restoration Institute, which won a $5 million grant from the 2022 Florida Legislature to plant 100 acres of seagrasses in areas where they’re needed most.

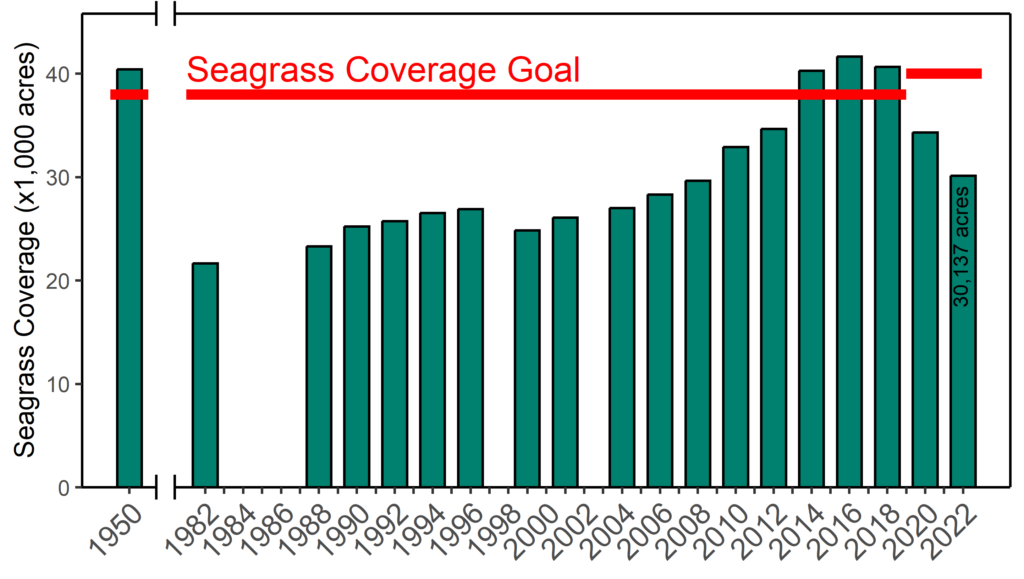

For decades, Tampa Bay’s seagrass acreage expanded as water quality improved. That changed beginning in 2018. Since then, more than 11,500 acres of a total 41,655 have been lost, although water quality parameters continue to meet targets. Across the state, in the Indian River Lagoon (IRL), nearly 60% of the estuary’s seagrasses – about 46,000 acres — have been lost over the past 12 years, causing an estimated 677 manatees to starve to death between December 2020 and May 2021.

No one is suggesting that seagrasses be transplanted in places where water quality is still an issue, but the technology to regrow seagrasses has been proven, Williams says. Not restoring seagrasses leads to a vicious cycle: seagrasses consume nutrients and their roots anchor sediments. When they die, excess nutrients fuel the growth of algae that block sunlight along with the released sediments.

And in estuaries like Tampa Bay and the IRL, seagrass losses across large areas mean that there are no seed sources or rhizomes that could spread, so it could take years, perhaps decades, for seagrasses to naturally repopulate those locations.

In the past, most transplanted seagrasses have been planted as part of an effort to mitigate for seagrasses that were unavoidably destroyed by a developer or government agency. At first glance, the research appears to show that seagrasses can’t be successfully transplanted, with only about a 38% success rate over the past 30+ years.

That’s misleading, though, say Williams and Ries. “What they saw was that barely 30% survived but that includes the older projects which did have a very low survival rate,” Ries said. “Over the past 10 years, it’s gotten much higher, with an average of 50 to 60% survival and even 100% in some locations.” And once successfully transplanted, 80% of those mitigated seagrasses are still alive.

The largest seagrass mitigation project in Tampa Bay occurred at Port Manatee when 5.5 acres of seagrasses were transplanted to allow for the construction of a new berth. “The port transplanted plugs that grew into a 20-acre seagrass prairie,” Ries said. “Transplanting seagrasses can be done successfully if they’re handled right.”

Williams, who has been transplanting seagrasses for more than 20 years, agrees. “I had a lady ask me about our success rate. I told her you don’t get to stay in business for that many years if you don’t do it right.”

However, success is highly dependent upon getting the design right, Williams adds. “You can’t just get together with some engineers who say ‘we need seagrasses to grow here.’ It just doesn’t work that way. Now we’ve gotten to the point where we won’t get involved in a project if we don’t have any say in the design. We’re not interested in doing the job because I don’t want failures on my resume.”

Williams, who was director of operations at Jim Anderson’s Seagrass Recovery Inc. prior to starting AquaTech in 2014, started growing seagrasses just east of Tampa near Eureka Springs, when a fish farm established in 1938 came on the market. “We don’t want to rob Peter from the wild to pay Paul, and the best way to avoid that is to grow seagrass in some type of a land-based system.”

Turning the overgrown fish farm into an aquaculture system was originally focused on freshwater grasses, or submerged aquatic vegetation. “We had a contract to put 120,000 plants in Lake Apopka for the St. Johns Water Management District. That was an easy task because the pipes were still here.” Saltwater seagrasses are more challenging, in large part because the 90-year-old concrete needs significant repairs before it can handle the more corrosive saltwater.

Going forward, AquaTech is planning to triple capacity for saltwater seagrasses at its Tampa location and then work with Ries to develop at least two more land-based sites as part of the Ecosphere grant.

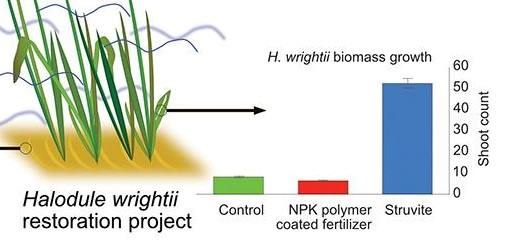

AquaTech also is working with the University of Florida on a study looking at struvite, a fertilizer developed as a byproduct of wastewater treatment plants that’s relatively insoluble. Seagrasses fertilized with it had an exponential increase in biomass compared to seagrasses to those grown with a standard time-released fertilizer or grown in a controlled setting. “Struvite is not soluble in water – it’s broken down by citric acid, which is produced by the plants’ roots as they’re growing, so the nutrients are only available when they’re needed,” Williams said.

The biggest challenge facing both AquaTech and Ecosphere isn’t how to grow or transplant seagrasses – they’ve proven that it can be done – but obtaining the regulatory permit authorizations for planting seagrasses can be difficult and has stymied efforts statewide. For example, replanting seagrass currently requires permits from the US Army Corps of Engineers, either the Florida Department of Environmental Protection or the local water management district, and, depending upon local regulations, a county.

That may change with new rules being considered by the FDEP that would allow experienced organizations using seagrasses grown in an aquaculture setting to obtain general permits. “There will be some constraints, but they’re common sense and should work well,” Williams said.